Stainless Steel 304 or 316 wire mesh sieves are suitable for sand control vibrating screen devices. Many R&D laboratories use this shaker to test and separate material, such as geology, chemicals, concrete medicine , defenses etc.

Sand Test Sieves are used to separate materials into various sizes for further processing or end use according to your needs. The material is separated by passing it through a vibrating "screen box", which has a number of different sized screens, or meshes, which the material falls through like a sieve, the material falls onto attached conveyors which stock pile the end products. The end products can then be used in the building and construction industries.

Sand Test Sieves Benefits:

1) High screening efficiency

2) High capacity and reliability

3) Long bearing lifetime

4) Easy maintenance

Features of Vibrating Screen Fitted with Sand Test Sieves:

Features

1. The frame is very tightly . This design enables clean screening, less screen wear and longer screen life.

2. As the screen vibrates in multiplane hence the holes of the screen remain clear.

3. This screen occupies less than half the spaces as occupied by any other screen of same capacity. Useful in wet screening The screen works on solid-liquid separation efficiently.

4. Due to vibrations in the vertical plane, blinding of screen is minimized. However, for certain materials which have inherent blinding, sticking

property and special accessories can be used to eliminate this problem.

5. There are no vibrations at the screen base. Even no flooring is needed. You can mount it on Bins, upper floors, planks or wherever it is most suited.

6. The design enables to utilize the vibratory force generated by the motor to the optimum and very few moving parts reduce the maintenance to minimum.

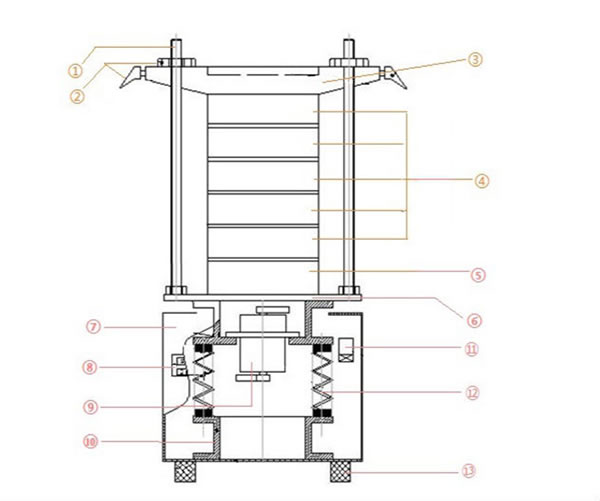

Structure

1.Supporting rod

2.Clamping nuts

3.Cover/Lid

4.Sieves/GB/T6003/SUS304/0.038-8mm

5.Receiver

6.Plate

7.Body

8.Swith

9.Motor/0.12KW/220V/50HZ/Single Phase

10.Spring bases

11.Timer

Main technical parameters

| Model | Screen deck |

Screen size (mm) |

Max. feed size (mm) |

Capacity (t/h) |

Vibrating frequency (Hz) |

Electric motor power (t) |

Weight (t) |

Overall Dimensions (mm) |

| 3YK-1245 | 3 | 1200 × 4500 | 200 | 15-80 | 16.2 | 11 | 4.807 | 5600 × 1800 × 1850 |

| 2YK-1548 | 2 | 1500 × 4800 | 200 | 30-180 | 13-16 | 15 | 5.800 | 5906 × 2100 × 1600 |

| 3YK-1548 | 3 | 1500 × 4800 | 200 | 30-200 | 13-16 | 15 | 6.866 | 5906 × 2100 × 1900 |

| 4YK-1548 | 4 | 1500 × 4800 | 200 | 30-250 | 13-16 | 18.5 | 7.360 | 5906 × 2100 × 2150 |

| 2YK-1854 | 2 | 1800 × 5400 | 250 | 50-300 | 16.2 | 18.5 | 6.769 | 6509 × 2536 × 1810 |

| 3YK-1854 | 3 | 1800 × 5400 | 250 | 50-300 | 16.2 | 22 | 8.285 | 6509 × 2536 × 1910 |

| 4YK-1854 | 4 | 1800 × 5400 | 250 | 50-300 | 16.2 | 30 | 9.796 | 6509 × 2536 × 2250 |

| 2YK-2160 | 2 | 2100 × 6000 | 250 | 100-400 | 16.2 | 30 | 9.680 | 7150 × 2670 × 2120 |

| 3YK-2160 | 3 | 2100 × 6000 | 250 | 100-400 | 16.2 | 30 | 10.206 | 7150 × 2670 × 2270 |

| 4YK-2160 | 4 | 2100 × 6000 | 250 | 100-400 | 16.2 | 30 | 11.800 | 7150 × 2670 × 2650 |

| 2YK2460 | 2 | 2400 × 6000 | 300 | 150-600 | 16.2 | 30 | 10.200 | 7150 × 2900 × 1950 |

| 3YK-2460 | 3 | 2400 × 6000 | 300 | 150-600 | 16.2 | 30 | 12.350 | 7150 × 2900 × 2350 |

| DF-1230 | 1 | 1200 × 3000 | 200 | 20-200 | 16.2 | 5.5 | 15.400 | 3500 × 1800 × 1100 |

| DF-1548 | 1 | 1500 × 4800 | 250 | 50-450 | 16.2 | 15 | 3.750 | 5330 × 2000 × 1300 |

| DF-1854 | 1 | 1800 × 5400 | 300 | 70-600 | 16.2 | 15 | 4.590 | 5630 × 2200 × 1320 |

| DF-2160 | 1 | 2100 × 6000 | 300 | 120-750 | 16.2 | 15 | 5.423 | 6550 × 2600 × 1420 |

Bolhes Test Sieve Co.