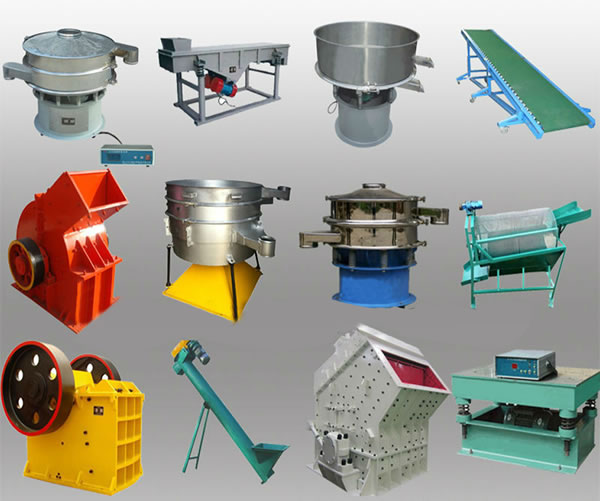

Flour mill sieves can be made with metal or polyester mesh bolting cloth as filtering material. It is a kind of Standard Sieves mainly used in flour milling.

Screening range: Any grain powder mucus inside certain limits are for screening and grading.

Flour mesh sieves are high efficiency accurate screening materials:

The specially designed sieves have a fully closed structure, the powder will not fly, the liquid don't disclose.

Major application of flour mill sieves:

1.Dry separation -Separation of different materials on the basis of their particle shape -Foods, chemicals, pharmaceuticals, minerals, animal feeds, grains;

2.Dry classification -Separation of solid particles into precise sized fractions -Foods, chemicals, minerals and metals, pulp and wood products, pharmaceuticals, fertilizers, abrasives

3.Solid/Liquid separation -Dewatering of solids and clarification of liquids -Foods, chemicals, pulp

4.Solids classification in liquid medium -Separation of solids into sized fraction in a liquid medium -Chemicals, minerals, pulp and paper, ceramics, waste disposal.

Features

1. High efficiency, elegant design & durable, available for any powder, particles and viscous liquid ;

2. The granularity may be raised by 1-70%,and the output may be improved to 10 times at most ;

3. The screen net is hardly plugged by even the most difficultly screened and materials the nature of the screened materials is not unchanged;

4. Seven popular sizes (400/600/800/1000/1200/1500/1800) to fit any requirement, space-saving and high volume ;

5. Simple structure, convenient installation and light weight; Reliable operation, long lifeexpectancy;Low electricity consumption.

Principal technical data of flour mill sieve

| circular flour sieves | ||||

| Model | Inlet diameter(mm) | Mesh Diameter | Effective Area | Power |

| FMS-1200 | 300 | 5~30 | 0.9331 | 1.5 |

Bolhes Test Sieve Co.