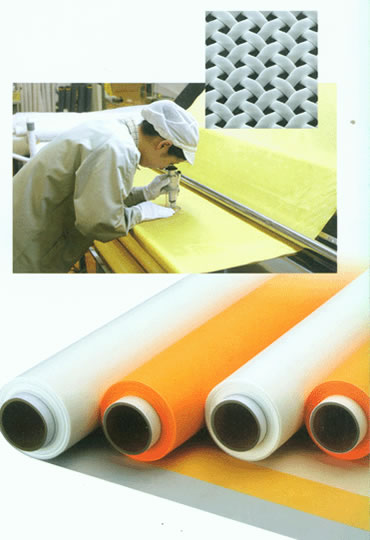

Bolhes supplies fine polyester mesh for screen printing with a mesh variety of 60mesh/ inch,80mesh, inch 100mesh/ inch,110mesh/ inch,120mesh/ inch and other sizes. Polyester screen is popularly used as bolting cloth or printing screen mesh.

Type: Monofilament Polyester Screen;Low-elongation Monofilament Polyester Screen; Multifilament Polyester Printing Screen.

Colour:White and Yellow

Width:127cm/160cm/165cm--360cm

Length:30m or 50m or 70m

Feature:High tension,low elongation,wear resistance,etc

Using:Polyester Printing Screen is widely used in electronic,textiles,ceramics and other industries for printing and filtration of aviation,airspace and petrochemical industries.

Detail Specification of Polyester Printing Mesh

| model | mesh count |

APERTURE | THREAD DIAMETER |

OPENING | thickness | INK THROUGH VOLUME THEORETICALLY |

| mesh / cm | micron | micron | % | micron | cm3/m2 | |

| 24-100 | 60 | 316 | 100 | 57 | 136-145 | 64.4 |

| 32-100 | 80 | 212 | 100 | 46 | 145-155 | 69 |

| 39-55 | 100 | 195 | 55 | 56 | 88-96 | 55.0 |

| 43-80 | 110 | 147 | 80 | 40.8 | 7-132 | 53 |

| 47-55 | 0 | 152 | 55 | 51 | 88-96 | 47.6 |

| 48-70 | 0 | 135 | 70 | 41 | 108-120 | 45.5 |

| 54-55 | 135 | 8 | 55 | 47 | 88-96 | 44.5 |

| 54-64 | 135 | 115 | 64 | 38.5 | 95-105 | 38.9 |

| 54-70 | 135 | 108 | 70 | 34 | 108-120 | 40 |

| 64-45 | 160 | 105 | 48 | 43 | 73-82 | 36.5 |

| 64-55 | 160 | 98 | 55 | 38 | 85-95 | 36.1 |

| 64-64 | 160 | 88 | 64 | 30 | 95-105 | 30.7 |

| 72-45 | 180 | 92 | 45 | 40 | 68-76 | 33.1 |

| 72-48 | 180 | 90 | 48 | 36 | 75-84 | 33.1 |

| 72-55 | 180 | 81 | 55 | 30 | 88-97 | 26.6 |

| 80-45 | 200 | 75 | 45 | 36 | 65-74 | 27.7 |

| 80-48 | 200 | 72 | 48 | 33 | 75-84 | 28.7 |

| 90-48 | 230 | 56 | 48 | 25 | 77-85 | 23.5 |

| 100-40 | 250 | 58 | 40 | 33 | 62-71 | 21.3 |

| 110-40 | 280 | 48 | 40 | 27 | 65-71 | 18.4 |

| 110-34 | 280 | 54 | 34 | 35.5 | 52-57 | 20.2 |

| 0-34 | 305 | 45 | 34 | 30.5 | 52-57 | 18.4 |

| 140-34 | 355 | 31 | 34 | 19.5 | 56-62 | 14.4 |

| 150-31 | 380 | 36 | 31 | 29 | 43-47 | 13.1 |

| 150-34 | 380 | 30 | 34 | 20.5 | 56-62 | 14.9 |

| 165-31 | 420 | 31 | 31 | 23 | 52-58 | 12.88 |

History and Characteristics of Polyester Printing Screen

Polyester was introduced to the screen printing market over 40 years ago and quickly replaced traditional silk as the fabric of choice among screen printers all over the world. It is a material that is uniquely suitable for screen printing because of its tensile strength, elastic memory and resistance to chemicals, abrasion heat and moisture.

There are 3 types of polyester fabrics used in screen printing and they are monofilament, low-elongation monofilament and multifilament. Most of today's screen printers use monofilament polyester, but the traditional type is rapidly being replaced with "Low-Elongation" fabric, which brings many new benefits to the screen printing process. Here we mainly introduce low-elongation monofilament polyester fabric as this is what we are producing now.

Monofilament Polyester is woven from yarn that is extruded from heated polyester into a single strand. The extruded thread is the spun to a precise diameter. Conventional monofilament polyester screen fabric will elongate under tension: the higher the tension level, the more the thread can stretch. At excessive tension levels, the thread reaches its "plastic deformation" point, and the screen will no longer hold tension.

Monofilament polyester is still suitable for non-critical printing applications. In recent years, however, it has been eclipsed by a new development in thread technology: Low-Elongation Polyester.

Low-Elongation Polyester is what we are producing now in a wide range of mesh counts, and our products offers significant advantages over the traditional monofilament polyester:

We may also take orders to produce polyester fiber mesh with other special requirements.

Bolhes Test Sieve Co.