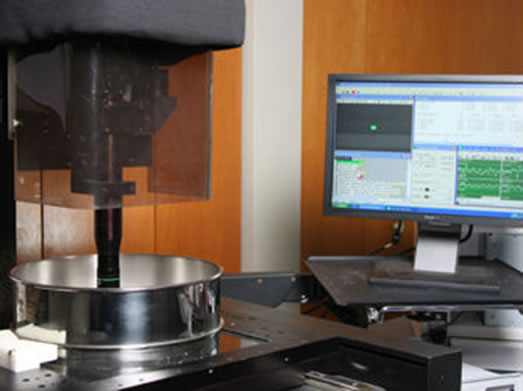

Laboratory Metal Sieves for testing and sizing are made from first class stainless steel woven wire cloth, brass mesh, bronze wire cloth or precisely punched perforated plate mesh. The sieves diameter varies from 12.5cm to 40cm. We also do customizable design.

Metal Sieves for Sizing and Screening

Bohes metal lab sieves offer the following benefits:

Long Screen Life:

The screen cloth is held in the frame very tightly by a special process. This design enables clean screening, less screen wear and longer screen life.

No Clogging of Screen:

As the screen vibrates in multiplane hence the holes of the screen remain clear. Additional and blinding system is provided for difficult to screen and wet materials.

Compact Design:

This screen occupies less than half the spaces as occupied by any other screen of same capacity. Useful in wet screening The screen works on solid-liquid separation efficiently.

Minumum blinding of screens:

Due to vibrations in the vertical plane, blinding of screen is minimized. However, for certain materials which have inherent blinding, sticking property and special accessories can be used to eliminate this problem.

Vibration free operation:

There are no vibrations at the screen base. Even no flooring is needed. You can mount it on Bins, upper floors, planks or wherever it is most suited.

Low on power and maintainence / High on efficiency:

The design enables to utilize the vibratory force generated by the motor to the optimum and very few moving parts reduce the maintenance to minimum.

| Metal test sieve(in ss materials) specification | ||

| Sieve Material | Stainless Steel 304/316/316L,etc. | |

| Technology | Woven | |

| Standard | ASTM E11-09 ISO3310-1 | |

| Sieve Diameter | 3" 6" 8" 10" 12" 200mm 300mm | |

| Frame | Material | SS brass , etc. |

| Height (full) | 1-3/4'' -- 2-5/8'' | |

| Aperture shape | Square | |

| Mesh opening / Aperture | 5--500mesh | |

| Standard Metal Testing Sieves ASTM Specification E-11 | ||||||

| Nominal Dimensions, Permissible Variations for Wire Cloth of Metal Standard Test Sieves Series | ||||||

| Sieve Designation | Norminal Sieve Opening inch (c) |

Permissible Variation of Average Opening from the Standard Sieve Designation | Opening Dimension Exceeded by not more than 5% of the openings | Maximum Individual Opening | Nominal Diameter mm (a) |

|

| Standard(b) | Alternative | |||||

| 125mm | 5" | 5 | ±3.70mm | 130.0mm | 130.9mm | 8 |

| 106mm | 4.24" | 4.24 | ±3.20mm | 110.2mm | 111.1mm | 6.3 |

| 100mm (d) | 4" | 4 | ±3.00mm | 104.0mm | 104.8mm | 6.3 |

| 90mm | 3.5" | 3.5 | ±2.70mm | 93.6mm | 94.4mm | 6.3 |

| 75mm | 3" | 3 | ±2.20mm | 78.1mm | 78.7mm | 6.3 |

| 63mm | 2.5" | 2.5 | ±1.90mm | 65.6mm | 66.2mm | 5.6 |

| 53mm | 2.5" | 2.12 | ±1.60mm | 55.2mm | 55.7mm | 5 |

| 50mm (d) | 2" | 2 | ±1.50mm | 52.1mm | 52.6mm | 5 |

| 45mm | 1.75" | 1.75 | ±1.40mm | 46.9mm | 47.4mm | 4.5 |

| 37.5mm | 1.5" | 1.5 | ±1.10mm | 39.1mm | 39.5mm | 4.5 |

| 31.5mm | 1.25" | 1.25 | ±1.00mm | 32.9mm | 33.2mm | 4 |

| 26.5mm | 1.06" | 1.06 | ±0.800mm | 27.7mm | 28.0mm | 3.55 |

| 25.0mm | 1.00" | 1 | ±0.800mm | 26.1mm | 26.4mm | 3.55 |

| 22.4mm | 0.875" | 0.875 | ±0.700mm | 23.4mm | 23.7mm | 3.55 |

| 19.0mm | 0.75" | 0.75 | ±0.600mm | 19.9mm | 20.1mm | 3.15 |

| 16.0mm | 0.625" | 0.625 | ±0.500mm | 16.7mm | 17.0mm | 3.15 |

| 13.2mm | 0.530" | 0.53 | ±0.410mm | 13.83mm | 14.05mm | 2.8 |

| 12.5mm (d) | 0.5" | 0.5 | ±0.390mm | 13.10mm | 13.31mm | 2.5 |

| 11.2mm | 7.0625" | 0.438 | ±0.350mm | 11.75mm | 11.94mm | 2.5 |

| 9.5mm | 0.375" | 0.375 | ±0.300mm | 9.97mm | 10.16mm | 2.24 |

| 8.0mm | 0.3125" | 0.312 | ±0.250mm | 8.41mm | 8.58mm | 2 |

| 6.7mm | 0.265" | 0.265 | ±0.210mm | 7.05mm | 7.20mm | 1.8 |

| 6.3mm (d) | 0.25" | 0.25 | ±0.200mm | 6.64mm | 6.78mm | 1.8 |

| 5.6mm | No. 3.5 (e) | 0.223 | ±0.180mm | 5.90mm | 6.04mm | 1.6 |

| 4.75mm | No. 4 | 0.187 | ±0.150mm | 5.02mm | 5.146mm | 1.6 |

| 4.0mm | No. 5 | 0.157 | ±0.130mm | 4.23mm | 4.35mm | 1.4 |

| 3.35mm | No. 6 | 0.132 | ±0.110mm | 3.55mm | 3.66mm | 1.25 |

| 2.8mm | No. 7 | 0.11 | ±0.095mm | 2.975mm | 3.070mm | 1.12 |

| 2.36mm | No. 8 | 0.0937 | ±0.080mm | 2.515mm | 2.600mm | 1 |

| 2.0mm | No. 10 | 0.0787 | ±0.070mm | 2.135mm | 2.215mm | 0.9 |

| 1.7mm | No. 12 | 0.0661 | ±0.060mm | 1.820mm | 1.890mm | 0.8 |

| 1.4mm | No. 14 | 0.0555 | ±0.050mm | 1.505mm | 1.565mm | 0.71 |

| 1.18mm | No. 16 | 0.0469 | ±0.045mm | 1.270mm | 1.330mm | 0.63 |

| 1.0mm | No. 18 | 0.0394 | ±0040mm | 1.083mm | 1.135mm | 0.56 |

| 850µm (d) | No. 20 | 0.0331 | ±35µm | 925µm | 970µm | 0.5 |

| 710µm | No. 25 | 0.0278 | ±30µm | 775µm | 815µm | 0.45 |

| 600µm | No. 30 | 0.0234 | ±25µm | 660µm | 695µm | 0.4 |

| 500µm | No. 35 | 0.0197 | ±20µm | 550µm | 585µm | 0.315 |

| 425µm | No. 40 | 0.0165 | ±19µm | 471µm | 502µm | 0.28 |

| 355µm | No. 45 | 0.0139 | ±16µm | 396µm | 425µm | 0.224 |

| 300µm | No. 50 | 0.0117 | ±14µm | 337µm | 363µm | 0.2 |

| 250µm | No. 60 | 0.0098 | ±12µm | 283µm | 306µm | 0.16 |

| 212µm | No. 70 | 0.0083 | ±10µm | 242µm | 263µm | 0.14 |

| 180µm | No. 80 | 0.007 | ±9µm | 207µm | 227µm | 0.125 |

| 150µm | No. 100 | 0.0059 | ±8µm | 174µm | 192µm | 0.1 |

| 125µm | No. 120 | 0.0049 | ±7µm | 147µm | 163µm | 0.09 |

| 106µm | No. 140 | 0.0041 | ±6µm | 126µm | 141µm | 0.071 |

| 90µm | No. 170 | 0.0035 | ±5µm | 108µm | 122µm | 0.063 |

| 75µm | No. 200 | 0.0029 | ±5µm | 91µm | 103µm | 0.05 |

| 63µm | No. 230 | 0.0025 | ±4µm | 77µm | 89µm | 0.045 |

| 53µm | No. 270 | 0.0021 | ±4µm | 66µm | 76µm | 0.036 |

| 45µm | No. 325 | 0.0017 | ±3µm | 57µm | 66µm | 0.032 |

| 38µm | No. 400 | 0.0015 | ±3µm | 48µm | 57µm | 0.030 |

| 32µm | No. 450 | 0.0012 | ±3µm | 42µm | 50µm | 0.028 |

| 25µm (d) | No. 500 | 0.001 | ±3µm | 34µm | 41µm | 0.025 |

| 20µm (d) | No. 635 | 0.0008 | ±3µm | 29µm | 35µm | 0.02 |

Bolhes Test Sieve Co.